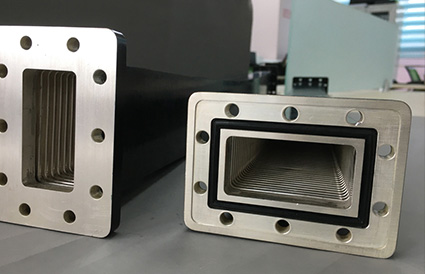

Raw material selection is the most important progress. As one of the most professional microwave waveguide manufacturers in China, all Dolph Microwave components in Aluminum is 6061 which has high intensity and rigid to guarantee the compoennts comleteness. All the assemble and raw material will do the quality measurement before production.

We are using the most advanced machine to do the production&processing. All our staff in workshop is specialized in microwave waveguide components machining for years. Each production will strictly follow the specific drawing and dimension confirmed.

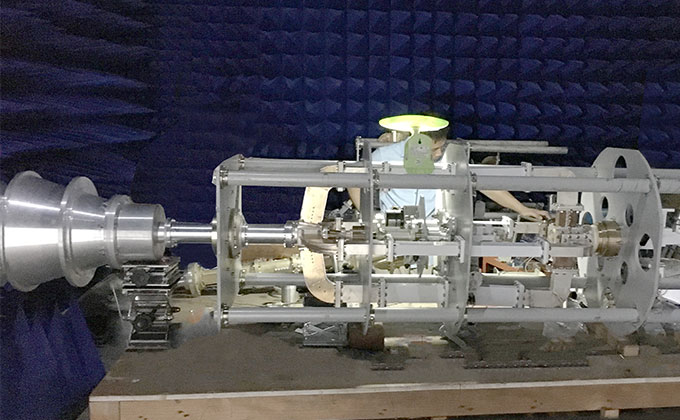

Test device is import with the latest model and parameter setup. Each product before delivery will do the systemetical test to confirm all parameter is same or superior than customer requirement. Test will include VSWR, IL and surface treatment, solt-foggy, IPX6 etc. based on detailed test requirement. The shipment will be approved when test parameter are qualified.

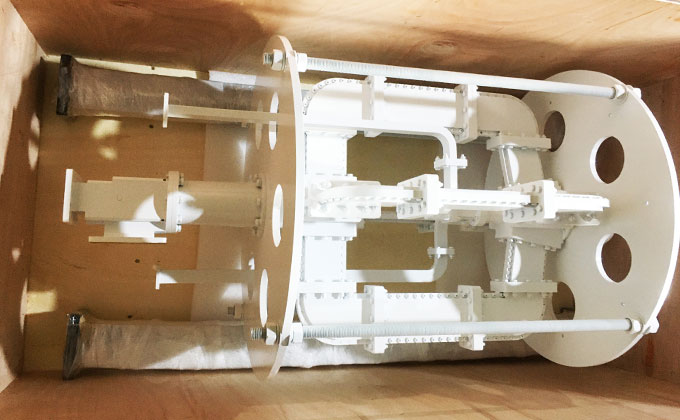

As a professional waveguide components supplier, all required in box will be confirmed especially test data before testing. The most proper packing is to avoid the damage during transportation. Each shipment will be chosen the mose suitable package like carton or wooden box.