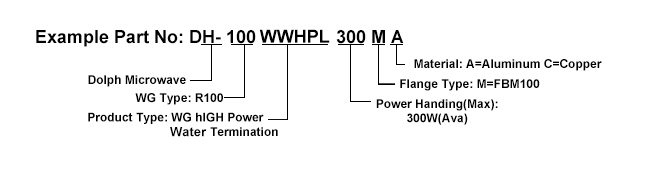

Dolph Microwave manufactures a line of Industrial Microwave Water Load. Double ridge waveguide Terminations are also available. Microwave components for industry microwave is 915 and 2450MHz.

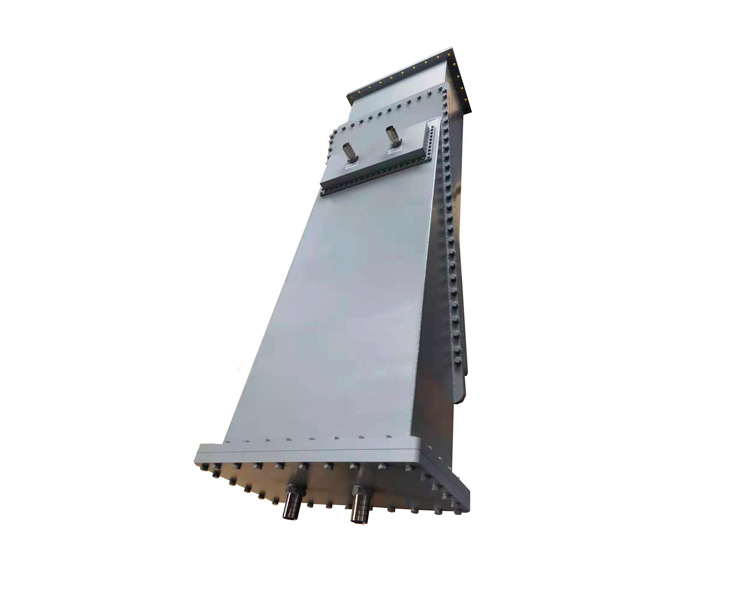

We offer a complete line of waveguide terminations in all waveguide sizes and power levels. Our Industrial Microwave Water Load, using flowing water as a microwave absorber and heat sink, has the advantages of large power capacity, bandwidth, small size, light weight and compact structure.

We also supply other special configurations to meet customer's specific requirements. Taking WR340(2450MHz) as example below.

WR340 High Power Water Load Waveguide Termination | |

Electrical Specifications | |

Model | DH-26WWHPL***(WR340) |

Frequency Range | 2450±25MHz |

VSWR | Max. 1.2:1 |

Average Power | Up to 15 KW |

Cooling Method | Water Load |

Flange | FDM26 (CPR 340G, UG553A/U) |

Material | Al |

Surface Treatment | Conductive Oxidation |

Water Injection | Quick Connector |

Water Flow | 3.8L/min |

Water Pressure | >0.14MPa |

Size | L130*W120*H90 mm |

In high-power microwave industrial application systems, there will be reflections during microwave transmission. Therefore, the Industrial Microwave Water Load are often used in industrial applications to absorb microwaves to protect the microwave source. As a commonly used terminal matching load, the Industrial Microwave Water Load is mainly composed of a waveguide transmission section and a microwave absorption cavity section.

The microwaves transmitted in the waveguide are absorbed by the cooling liquid flowing in the water chamber and converted into heat energy. The greater the power absorbed by the load, the higher the temperature in the absorption cavity, and the faster the cooling liquid temperature rises. The cooling liquid needs to maintain a certain flow to meet the power capacity requirements, otherwise the water load temperature rises too high, and the microwave absorption will deteriorate.

More industrial microwave components may interest you