Industrial Microwave Tuners are waveguide components used to match the load impedance with the source impedance. They minimize the amount of reflected power, providing the most efficient coupling of power to the load. Dolph Microwave supplies both manual 3- and 4-stub tuners, electrical and auto tuners. Industrial Microwave Tuners utilize manual tuning and lock simply. They are generally used in applications where the load impedance varies significantly due to variations in the load. Microwave components for industry microwave is 915 and 2450MHz.

Taking the WR340 for example.

WR340 Waveguide Tuner | |

Electrical Specifications | |

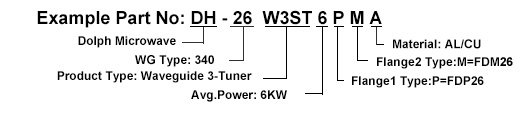

Model | DH-26W3ST6PPA(WR340) |

Frequency Range | 2450±25MHz |

VSWR | 1.1-10 (Tuning Range) |

Power Handling | 6 KW |

Cooling | Air |

Tuning | Manual |

Mechanical Specifications | |

Waveguide Type | WR340 |

Flange type | FDP26 (Cover) |

Material | Aluminum |

Inside finish | Conductive Oxidation |

Outside finish | Anticorrosion Black Paint |

Dimension | As below |

Industrial Microwave Tuners is a common impedance adjust. The depth, spacing and radius of the pins can be set as required. It is a common device for impedance matching in high-power microwave systems.

When a metal pin of a certain diameter is inserted along the center of the broad side in the waveguide, its equivalent circuit is parallel susceptance. When the insertion depth of the pin is shallow, the pin mainly acts as a concentrated electric field, and the equivalent susceptance of the pin is capacitive. As the insertion depth of the pin increases, the capacitance increases, and at the same time, the axial current on the broad side of the waveguide flows along the axial direction of the pin, thereby generating a magnetic field and making the pin have a certain inductance. LC series loop on the main line. The resonance of the pin is related to the operating wavelength, insertion depth and width of the narrow side of the waveguide.

More industrial microwave components may interest you